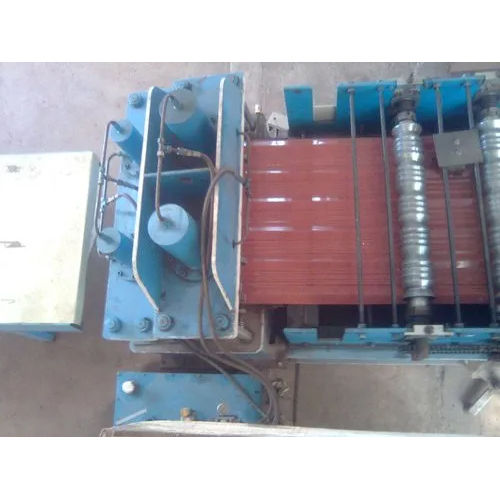

Reversible Cold Rolling Mill Machine

Price 3600000 INR/ Unit

MOQ : 1 Unit

Reversible Cold Rolling Mill Machine Specification

- Material

- Stainless Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Frequency Speed Control

- Warranty

- Yes

Reversible Cold Rolling Mill Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Reversible Cold Rolling Mill Machine

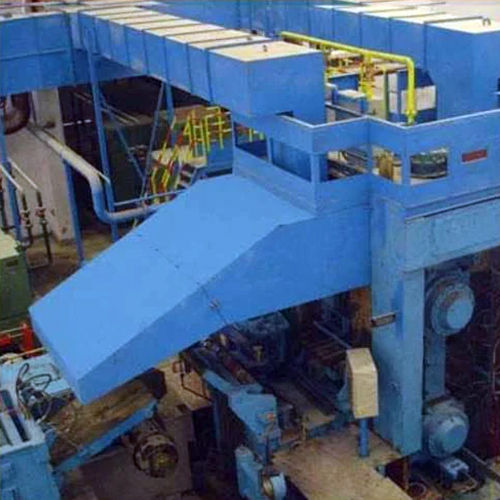

The Reversible Cold Rolling Mill Machine is meticulously crafted to provide exceptional performance in cold rolling operations. Employing cutting-edge technology, it enables precise and efficient rolling of various materials with reversible functionality, enhancing productivity. Its sturdy construction ensures durability and reliability for continuous operation in industrial settings. Equipped with intuitive controls and customizable settings, it offers versatility to meet diverse rolling requirements. Whether for steel, aluminum, or other metals, this machine delivers consistent quality and precision, elevating cold rolling processes to new heights of efficiency.

Efficient and Versatile Metal Processing

Designed to streamline cold rolling processes, this semi-automatic machine offers durability with its stainless steel build and advanced speed control system. Its reversible function allows easy direction change, reducing downtime and improving workflow efficiency. Supported throughout India, its the perfect solution for small to medium-scale metal sheet and strip production.

Reliable Solutions by Leading Industry Providers

Whether you operate as a manufacturer, supplier, trader, or distributor, this cold rolling mill promises user-friendly operation and long-lasting service, further secured by a product warranty. With readily available support from Indian service providers, plant managers and operators gain peace of mind for maintenance, operation training, and troubleshooting.

FAQs of Reversible Cold Rolling Mill Machine:

Q: How is the reversible cold rolling process achieved with this semi-automatic mill?

A: The reversible cold rolling process utilizes the machines capability to alternate the rolling direction, allowing the metal sheet or strip to pass back and forth until the desired thickness is reached. This is managed through the frequency speed control system, which enables precise adjustments without the need for full automation.Q: What are the main benefits of using a semi-automatic reversible cold rolling mill?

A: Benefits include greater control over the rolling speed due to the frequency control system, reduced operator fatigue because of semi-automation, improved surface finish of metal products, and increased versatility for different steel grades. Its robust stainless steel construction also ensures longevity and consistent production quality.Q: When should I consider using this cold rolling mill for my manufacturing process?

A: You should consider this cold rolling mill when you require a reliable, cost-effective solution for reducing the thickness of steel strips or sheets, especially if you do not need a fully computerized system but want dependable speed control and warranty-backed support.Q: Where can I purchase or service this cold rolling mill in India?

A: This machine is available through a network of manufacturers, distributors, suppliers, traders, and service providers across India. After-sales support, installation, and maintenance services are also provided to ensure smooth operation and maximum uptime.Q: What is the process of operating this semi-automatic cold rolling mill?

A: To operate, the user loads the stainless steel sheet or strip, sets the required speed using the frequency control system, and manages the reversing rolling action as needed. The process continues until the material reaches the target thickness, after which the machine can be reset for new batches.Q: How does the frequency speed control system enhance machine usage?

A: The frequency speed control system enables operators to fine-tune the rolling speed according to material specifications, thus ensuring a uniform product finish and reducing material waste. It offers flexibility and energy savings compared to fixed-speed models.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Roll Forming Machine Category

Tile Profile Roll Forming Machine

Price 320000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Material : Stainless Steel

Computerized : No

Manual Decoiler

Price 100000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Material : MS

Computerized : No

Type : Manual Decoiler

TECHNO MACHINE TOOLS

GST : 36AELPT9784K1ZC

GST : 36AELPT9784K1ZC

Survey No.126/a/1, Door No.4-132-7/a/2, Gandimaisamma X Road, Medchal, Malkajgiri,Hyderabad - 500044, Telangana, India

Phone :08071794443

Mr Talam Sivarama SivaramaKrishna

(Managing Director (M.E., MBA.,))

Mobile :08071794443

|

|

TECHNO MACHINE TOOLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry